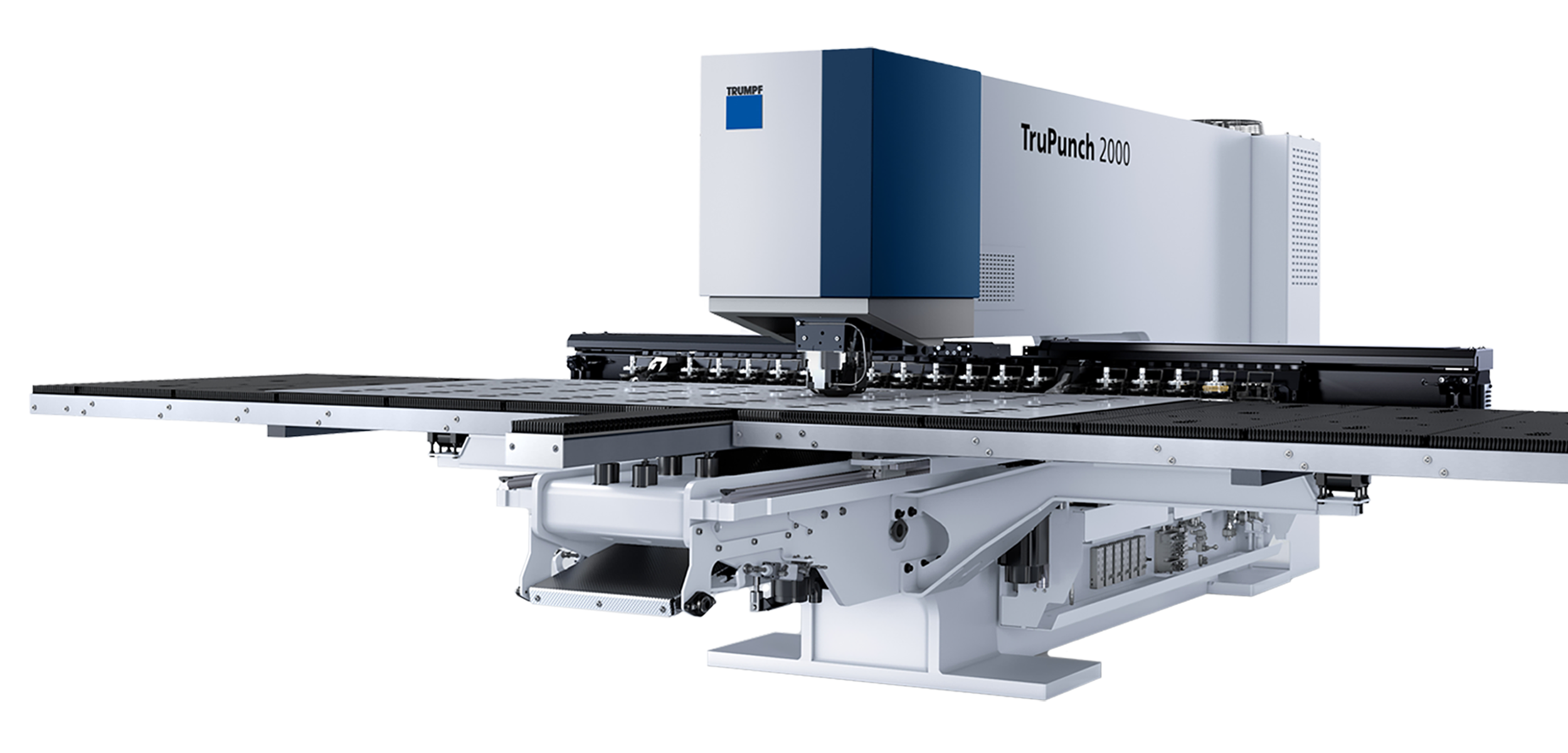

In 2022, we have expanded our machinery by the new generation punching machine from Trumpf - TruPunch 3000 - fully automatized. TruPunch 3000 is the ideal solution for versatile part processing. Even with the easy control and operating through the touchpoint HMI.

This new punching machine can punch, form, tap emboss, mark, engrave and deburr. TruPunch increases our effectivity and is capable of a long-term operation, with low dependability on the human source.